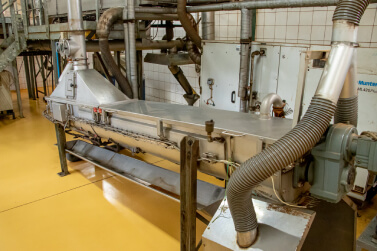

The state-of-the-art SAFESTERIL® sterilisation technology available at CSC consists of patented European Technologies, from its heating screw, all the way to its steam chamber and flash cooler. The unit provides a homogenous and efficient treatment via excellent product mixing mechanisms, ensuring minimum process & volatile oil losses, and minimum organoleptic changes in products.

SAFESTERIL® is based on the patented technology that consists of Spirajoule® (an electrical heating system which could be used for sterilization, drying, roasting, toasting and pre-cooking), and UPX®, a patented flash cooler, from ETIA France.

The system offers customers an environmentally friendly and cost-effective decontaminating solution for exporters.

Technology We Use

Steam Sterilization

SAFESTERIL EU Patented Technology for safe & efficient sterilization whilst safeguarding Volatile oils.

Milling

Cutting edge technology ensuring food safety and product quality.

Pre-cutting

Offering a wide range of granular sizes (0.5mm – 20mm) with high yields.

Fine grinding

Offering a wide range of fine powdering solutions (60 – 2500 Mesh size)

Cooling

Ensuring minimum Volatile oil losses during milling.

Food Safety

Magnet strips placed at multiple locations and many more controls.

PLC Controls

All operations controlled via PLC.

Steam Sterilization

SAFESTERIL EU Patented Technology for small batch volumes.

Infrastructure

Capability to handle large volumes of Raw Materials efficiently and effectively.